The Conform ™ Process

Conform ™ Extrusion Technology

The use of a single revolving wheel as the driving force in the Conform continuous rotary extrusion (CRE) process enables the manufacture of products of unlimited length. In its simplest form the wheel has a single groove in its periphery which accepts the feedstock and transfers the material to the extrusion zone and die.

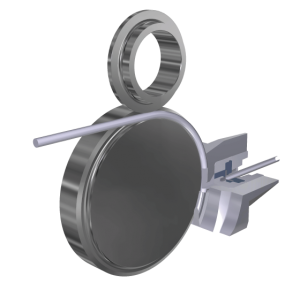

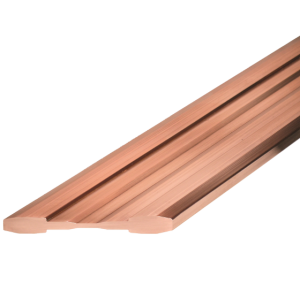

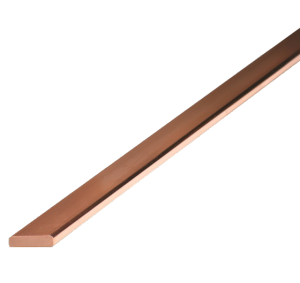

The diagram shows the configuration used for the production of most solid and hollow sections. A die chamber, carrying the appropriate die, is supported in a shoe. The die chamber incorporates an abutment that protrudes into the wheel groove. The force applied by the rotating wheel causes the feed material near the abutment to flow plastically into the die chamber and extrude through the die. Whilst the feedstock is usually in the form of rod, the process can also operate with material of any morphology provided that it can be fed into a suitably sized groove.