The Conklad ™ Process

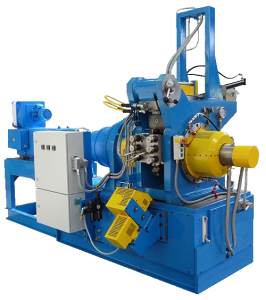

In the 1980’s BWE pioneered the development of cladding and sheathing using the Conform continuous rotary extrusion (CRE) method. This work led to the introduction of Conklad, which has become the industry standard for many applications.

Conklad ™ Extrusion Technology

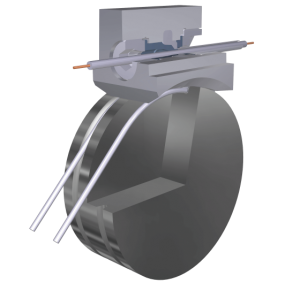

The geometry of the Conklad process is arranged so that a central core can be introduced inside the extrusion. Twin or Single feedstock rods are used to produce two flows of metal on either side of the chamber so that the pressure around the central core is balanced.

The Conklad process has two formats –

The greatest advance in Conform technology has been achieved by BWE in the application of the process for the sheathing or cladding of temperature sensitive (soft) or hard cores as they pass through the extrusion tooling.