Going Green in Germany

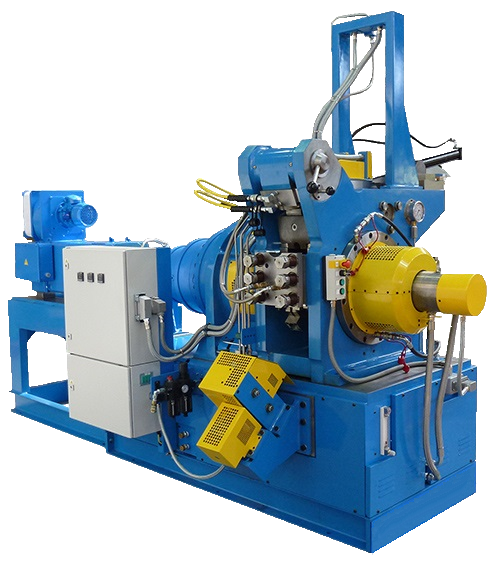

Following extensive trials at BWE’s headquarters in Ashford, the Institute for Metal Forming (IMF) in Freiburg (Germany), invested in a Conform™ 315i machine for their ongoing research and development in light metals (i.e. magnesium). Dipl.-Ing. Christoph Kaden of the IMF explains: The new Conform™ 315i expands the IMF’s capabilities to produce long products of light […]